While the FT 900 is an entry-level thermo-foil press, it is anything but basic. For example, new users will find a built-in tutorial on the touch screen that answer virtually any question they need to ask, and also supplies hints to simplify and control the process. And one if its most distinctive attributes is a very large vacuum pump that is simply not fond on competing machines. That 30 CFM unit will produce near absolute vacuum, thus ensuring complete forming of the film over the part and shortening the cycle time.

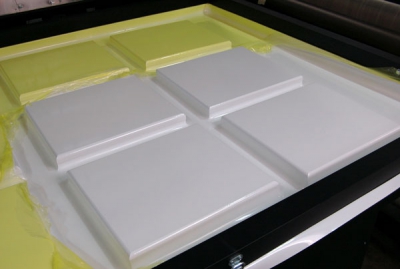

Vac-U-Clamp offers an optional set of ‘non-stick” coated platens for the FT 900. These prevent pre-glued film from sticking to the machine, without having to use (and clean up) a messy non-stick spray releasing agent. That saves a lot of set-up time between cycles, and contributes to a cleaner work environment, and better results.

Experienced users will also appreciate the momentary vacuum flow button, which helps to eliminate wrinkles in large panels. Located on the touch screen, this is especially handy when working with large panels where film might prematurely stick to the work and prevent it from properly shrinking, thus causing wrinkles.

One of the strength of this machine is that it is entirely made in the USA, which in these days of tariffs is a serious consideration. While overseas manufacturers may need to trim costs by downgrading component quality, shops using the FT 900 know that OEM parts and service questions are still of the very highest quality, and they are not located at the other side of the planet. And that service is based on three decades of experience specializing in both heated and unheated, industry leading vacuum presses.

Let’s talk about some specifics. The FT 900 can handle work up to an impressive 52″ x 105″ in an overall footprint that is only 112″ wide and 74″ front to back (and that include the control console and the top lift arms!). For height, it sits at 44″ (48″ with castors). The typical cycle time is 6.5 to 7.5 minutes, depending on film color and type, so the machine can deliver about fifty parts per hour (that’s around 1,800 to 2,000 parts in a typical week).

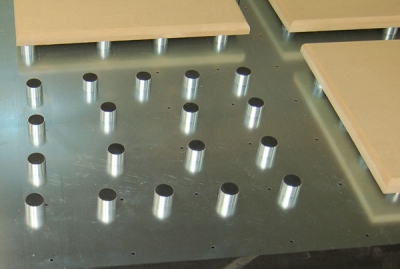

The FT 900 is built to work hard. It runs on a 3-phase, 240 volt power ( 60 amps ), and is rugged frame is TIG welded, aircraft quality, heavy wall aluminum tubing with a very durable, power-coated, cold rolled 18-gauge steel skin. The large vacuum pump is liquid cooled, and there’s a 30-gallon reserve tank that helps air evacuate rapidly. That feature substantially reduces cycle time.

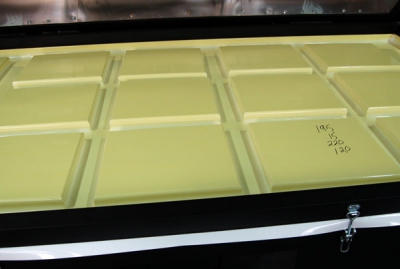

When the FT 900 won’t be working all out ( for example, when you’re just making sample or repairing a single panel), pre-installed divider bar tabs allow the operator to reduce the platen area by one there or even half its length, to avoid wasting expensive film.

During operation, the infrared quarts heating elements produce 21,600 Watts and they’re arranged to avoid cool spots that are common in less well-engineered presses. And anyone who has spent time pre-cutting film will appreciate the two 3″ diameter rear mounted pistons that help create a clear path to pull the film through.

Ease of operation is also enhanced by the IDEC 8.5″ color touch screen that can handle up to five separate programs for different kinds of film. The screen also plays tutorial FAQ videos that can be updated through a built in USB port. Vac-U-Clamp offers such updates at no cost. In fact , all program updates can be easily loaded through the USB ports as on follows some basic instructions on the tutorial section of the screen – another Vac-U-Clam exclusive feature. The FT 900 comes with a 1 year warranty.