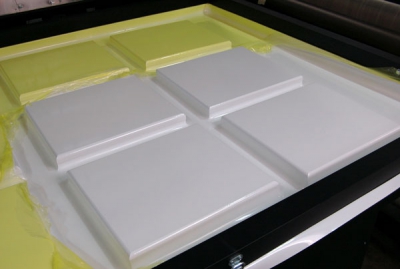

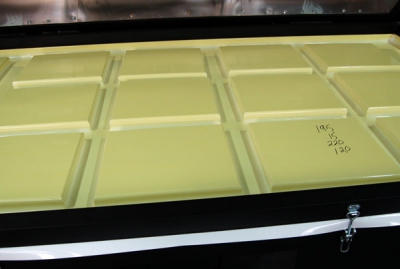

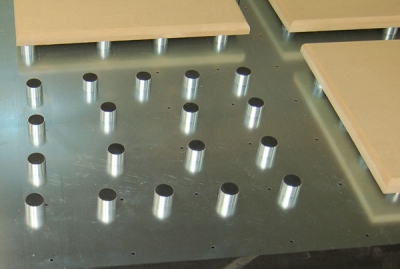

With the FT-900M dual purpose machine, you get a multi-use vacuum press that can thermo-foil or veneer/laminate. Utilize the silicone membrane frame that comes standard with the FT-900M, and you’re veneering, laminating & forming all of your projects fast & easy. Simply remove the membrane frame and thermo foil is your domain !! You would be hard pressed to find a more versatile machine on the market for this price.

The new FT600M also features this dual purpose design for a smaller price tag. Call us if you’re interested !

The FT-900M Goes Hollywood