The term vacuum pressure is complex and often misunderstood. Kinda like understanding diamonds. Consequently, it is commonly misapplied when discussing pressure measurements. Basically pressure is the exertion of force onto an object, in our case, a cabinet door, MDF or formed plastic for an auto or airplane console. Vacuum pressure by definition is the “space that is partially exhausted by artificial means such as a pump to the highest degree possible”. Vacuum pressure is expressed in inches of mercury or -Hg (Hg being the chemical abbreviation for mercury). For example, -1″ of Hg equals 70.7 lbs per square foot or .49 psi (more commonly expressed in psi) . See below table borrowed from George Guise.

1 Hg = 0.4912 Lbs/Square Inch

1 Hg = 70.7300 Lbs/Square Foot

Inches Hg Lbs/Sq. In. Lbs/Sq. Ft.

1 0.49 70.73

2 0.98 141.45

3 1.47 212.18

4 1.96 282.91

5 2.46 353.63

6 2.95 424.36

7 3.44 495.09

8 3.93 565.82

9 4.42 636.54

10 4.91 707.27

11 5.40 778.00

12 5.89 848.72

13 6.39 919.45

14 6.88 990.18

15 7.37 1060.90

16 7.86 1131.63

17 8.35 1202.36

18 8.84 1273.08

19 9.33 1343.81

20 9.82 1414.54

21 10.31 1485.27

22 10.81 1555.99

23 11.30 1626.72

24 11.79 1697.45

25 12.28 1768.17

29.92 14.70 2116.15

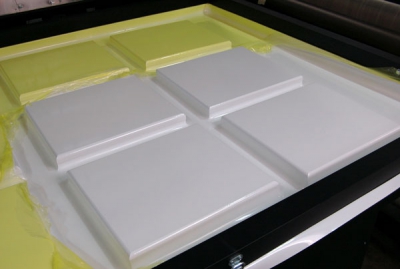

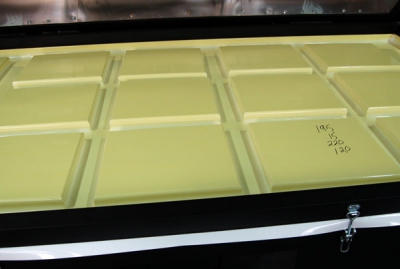

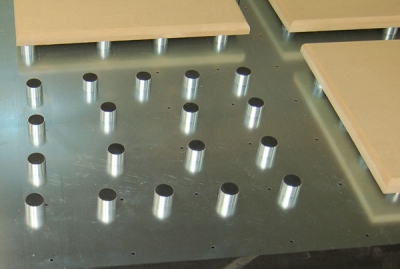

So doing the math, vacuum pressure can be very powerful and a useful tool. In working with wood, plastics, foam and others substrates, it was discovered that vacuum pressure solved many problems for veneering, lamination and forming. A good vacuum pump is capable of producing over – 21″ of Hg or 1485 lbs per square foot. Yes that’s right. You can have thousands of pounds of pressure exerted on your project or parts using good production pumps and membranes. Vac-u-Clamp touts rotary vane technology which is capable of exerting 2100 pounds per square foot or over 60,000 lb exerted on a large panel at full vacuum. Think that will help with veneering or laminating? “Better believe it” as my grandpa would say. Vacuum pump systems are capable of generating incredible force and is what makes a vacuum press an integral component to proper and effective bonding & forming. Using this technology, Vac-u-clamp SP & FP Series presses not only press the veneer onto the substrate, it compresses the fibers of the materials being glued. As the fibers are compressed, the air inside of the materials is displaced with glue and within usually an hour or two on MDF, a bond is complete.