FT SERIES – AT THE CROSSROADS OF

IN-HOUSE CONTROL/PRODUCTION & AFFORDABILITY

In a post-COVID economy, it is expected that significant changes in consumer behavior, business operations, and government policies will continue to shape and shift the way we do business. The pandemic has accelerated the adoption of remote work, e-commerce, leading to a shift in the way people work, shop, and communicate. The pandemic has also highlighted the importance of resilience, agility, and sustainability in the economy. Vac-u-Clamp has recognized this and the importance to pivot and assist our customers anyway we can.

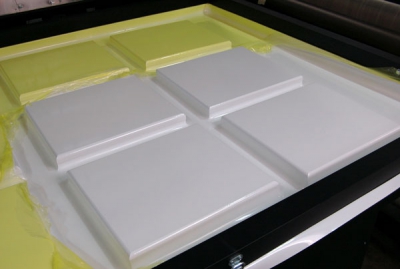

One way we have set out to help strained budgets and uncertain economics is the introduction of the FT600 Thermo Foil Press. Designed with the same components as the flagship FT900 (still our most popular press) it’s nice to know that quality production and affordability can coexist in one machine. Many of you remember and perhaps learned thermo foiling of our heritage FT-800 press. In 2020, with improvements in performance and automation, the latest FT-900 & FT-1200 thermo foil presses carry on the tradition of Vac-u-Clamp quality. These presses embody the value proposition of saving money while putting high production & production control at your finger tips. In 2021, we launched the FT-600 for smaller demand & smaller budgets and this press is even available on a rent to own basis. Please inquire if this interests you.

Some companies charge $150,000 or more for high production. Vac-u-Clamp’s FT Series starts in the $30K range and is fully equipped and can easily meet a tough production demands of 1000 to 7000 parts per week. Be it small cabinet doors for kitchen remodels or large 4×8 barn door sliders for the living area, the FT’s can meet the production demand you have, provide the quality your customer expects and at the price you can be comfortable with.

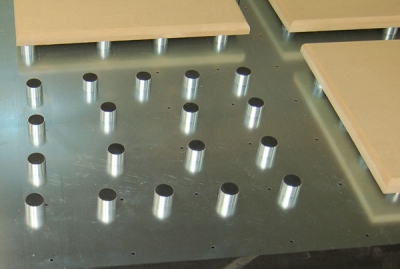

Constructed of high strength aluminum & steel at our Oceanside, California facility, the FT Series comes in three different sizes.

-

The FT-600 is our entry level low production model that is built with affordability & space savings in mind. Nimble but powerful, it’s about 1/3 smaller, cheaper and in production output than it’s big brother the FT-900, Great for smaller operations just getting started or that have a mix of high and mid-range remodels on their books. It sells for about $30,000 USD.

-

The FT-900 is our medium production model and our flagship thermo-foil press. Small in foot print but large on output, the FT-900 is easily capable of finishing 4000 to 5000 cabinet doors per week. Built with the single operator in mind, this design has an automated hinge style lifting top that actuates with a touch of a button. Imitated by many, duplicated by none. (including our friends in Orange County that import cheap Chinese knock offs and say they manufacture them in the US).

-

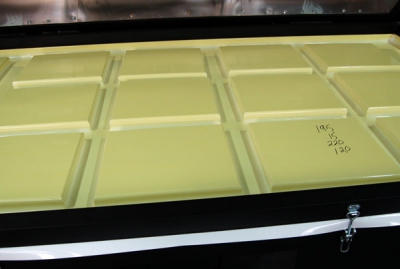

The FT-1200 is our high production platform that can produce 5000 to 8000 cabinet doors per week and is available in dual or mono “shuttle” design. The design allows for 360 degree platen accessibility for one or two operators. Output rated at 8000 parts per week equals maximum output with minimal manpower. Surprisingly this press is much less than $100K and is used my many famous household manufacturers.

All of the FT’s come standard equipped with a 9″ digital touch screen for ultimate ease of control and operation, 20,000+ watts of heat for fast reliable heating capability for consistent quality in your part production and a state of the art, digital PLC control panel for safety, reliability and pre-set capability to store favorite film preheat times, draw down durations and other heat recipes when programming for different types of thermo films.

Available in 220/240 VAC or 440/460/480 VAC 3 phase Power options and all electrical components are UL, CSA or CE listed, approved or certified.

Thermo Foiling is a growing market trend as solid wood prices rise and become more scarce. Many remodel professionals are using thermo film to join with MDF for a cost effective, quality look with many colors to choose from. We can train you on site when you purchase a new machine from us. We are experts on thermo foil and we’ll even train you on how to do a six sided, full wrap on full size doors using our proprietary recipe of heat, adhesive & time.